Mastering the Art and Science of Textile: The Comprehensive Guide to Dyeing and Finishing Specialists

In the realm of textiles, where fibers transform into fabrics and threads weave stories of creativity, the role of Dyeing and Finishing Specialists emerges as a crucial linchpin. These specialists stand at the intersection of art and science, employing their expertise to imbue textiles with color, texture, and functionality. In this comprehensive guide, we embark on a journey into the world of Dyeing and Finishing Specialists, exploring the intricacies of their roles, the skills they command, the challenges they navigate, and the transformative impact they have on the textile industry.

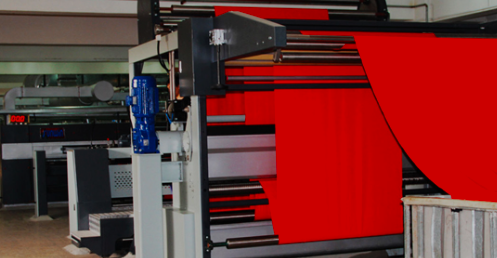

The Artistry and Precision of Dyeing and Finishing

Dyeing and Finishing Specialists play a pivotal role in the textile production process, contributing to the aesthetics, durability, and overall quality of fabrics. Their responsibilities span from color application to enhancing the physical properties of textiles, ensuring that the end products meet both artistic and functional expectations.

Key Responsibilities of Dyeing and Finishing Specialists:

- Color Application: Applying dyes and pigments to textiles to achieve desired colors and patterns, collaborating closely with Textile Colorists.

- Finishing Techniques: Implementing various finishing techniques such as calendering, heat-setting, and coating to enhance the texture, hand feel, and performance of fabrics.

- Quality Assurance: Conducting rigorous quality control checks at each stage of the dyeing and finishing process to ensure adherence to industry standards.

- Process Optimization: Continuously evaluating and optimizing dyeing and finishing processes for efficiency, resource utilization, and waste reduction.

- Problem Solving: Addressing issues related to color fastness, uneven dyeing, or finishing irregularities, employing problem-solving skills to achieve desired outcomes.

- Collaboration with Designers: Collaborating with designers and Textile Colorists to translate creative visions into feasible and reproducible dyeing and finishing processes.

- Technical Expertise: Staying abreast of advancements in dyeing technologies, finishing equipment, and sustainable practices to maintain technical proficiency.

- Environmental Considerations: Implementing eco-friendly dyeing and finishing practices, considering the environmental impact of chemicals and processes.

Essential Skills for Dyeing and Finishing Specialists

The role of Dyeing and Finishing Specialists demands a unique blend of artistic sensibility, technical acumen, and problem-solving skills. Here are key skills essential for excelling in this specialized field:

1. Color Matching:

- Precision: Achieving precise color matching as per specifications provided by Textile Colorists and designers.

- Consistency: Ensuring consistency in color application across different batches and types of fabrics.

2. Technical Proficiency:

- Chemical Knowledge: Understanding the chemical properties of dyes, pigments, and finishing agents.

- Equipment Operation: Proficiency in operating and maintaining dyeing and finishing machinery.

3. Quality Control:

- Attention to Detail: Meticulously inspecting fabrics for quality, identifying and rectifying any defects.

- Testing Protocols: Implementing standardized testing protocols for color fastness, shrinkage, and durability.

4. Problem-Solving:

- Analytical Thinking: Employing analytical thinking to troubleshoot issues related to dyeing and finishing processes.

- Adaptability: Adapting processes to address challenges and achieve desired outcomes.

5. Communication Skills:

- Collaboration: Effectively communicating with Textile Colorists, designers, and production teams to align on color and finishing requirements.

- Documentation: Clearly documenting dyeing recipes, finishing processes, and quality control measures.

6. Time Management:

- Efficiency: Managing time efficiently to meet production schedules and deadlines.

- Workflow Optimization: Streamlining workflows to enhance productivity without compromising on quality.

7. Environmental Awareness:

- Sustainable Practices: Integrating sustainable and eco-friendly practices in dyeing and finishing processes.

- Chemical Disposal: Responsible disposal of chemicals to minimize environmental impact.

8. Adaptability:

- Technology Integration: Adapting to advancements in dyeing and finishing technologies, including automation and digitization.

- Continuous Learning: Keeping abreast of industry trends and new techniques through continuous learning.

Challenges Faced by Dyeing and Finishing Specialists

While the role of Dyeing and Finishing Specialists is indispensable, it comes with its set of challenges that require expertise and resilience to overcome:

1. Color Consistency:

- Fabric Variation: Dealing with variations in fabric types and compositions that can influence how colors are absorbed.

- Dye Lot Variations: Managing variations in dye lots, especially in large-scale production, to maintain color consistency.

2. Quality Control:

- Uniformity Challenges: Ensuring uniformity in dyeing and finishing across the entire fabric, addressing issues like streaking or blotchiness.

- Meeting Standards: Adhering to stringent quality standards and customer expectations for every batch.

3. Environmental Regulations:

- Chemical Compliance: Complying with environmental regulations regarding the use and disposal of chemicals in the dyeing and finishing processes.

- Sustainability Practices: Balancing sustainability practices with the need for cost-effective and efficient production.

4. Technological Shifts:

- Adopting New Technologies: Navigating the integration of new technologies, such as digital dyeing machines or automated finishing processes.

- Training Challenges: Training teams to adapt to technological shifts and ensuring seamless implementation.

5. Customization Demands:

- Bespoke Requirements: Addressing the growing trend of customization and bespoke dyeing and finishing requirements.

- Efficiency in Small Batches: Maintaining efficiency in smaller production batches with varied specifications.

6. Resource Utilization:

- Energy and Water Consumption: Managing and optimizing the consumption of energy and water in dyeing and finishing operations.

- Waste Reduction: Implementing strategies for minimizing waste generated during the dyeing and finishing processes.

Opportunities in Dyeing and Finishing Specialist Careers

Amidst challenges, Dyeing and Finishing Specialists find numerous opportunities to innovate, contribute to sustainability, and align with evolving industry trends:

1. Sustainable Practices:

- Eco-Friendly Dyes: Exploring and implementing the use of eco-friendly and biodegradable dyes.

- Waterless Dyeing Technologies: Adopting waterless dyeing technologies to reduce water consumption.

2. Digitalization of Processes:

- Automation: Embracing automation for precision in dyeing and finishing processes.

- Digital Dyeing: Exploring digital dyeing technologies for accurate color application and customization.

3. Customization Trends:

- Small-Batch Production: Capitalizing on the trend of small-batch and customizable production.

- Collaboration with Designers: Collaborating with designers to offer unique and bespoke dyeing and finishing solutions.

4. Training and Education:

- Skill Development Programs: Initiating skill development programs for teams to stay updated on new technologies and techniques.

- Educational Outreach: Contributing to educational programs that focus on dyeing and finishing processes.

5. Energy-Efficient Technologies:

- Renewable Energy Adoption: Incorporating renewable energy sources to power dyeing and finishing operations.

- Energy-Efficient Equipment: Investing in energy-efficient dyeing and finishing equipment.

6. Collaboration with Sustainable Brands:

- Partnerships with Eco-Friendly Brands: Collaborating with sustainable fashion brands to align dyeing and finishing processes with eco-conscious values.

- Transparent Practices: Adopting transparent practices that resonate with environmentally conscious consumers.

7. Innovation in Textile Finishing:

- Smart Textiles: Exploring innovations in smart textiles through advanced finishing techniques.

- Multi-Functional Finishes: Developing finishes that offer multiple functionalities, such as water repellency and antimicrobial properties.

Future Trends in Dyeing and Finishing Specialist Careers

As the textile industry evolves, Dyeing and Finishing Specialists must anticipate and embrace future trends to stay ahead in a competitive and dynamic landscape:

1. Digital Transformation:

- The integration of digital technologies, including IoT and data analytics, for real-time monitoring and control of dyeing and finishing processes.

2. Biodegradable and Smart Finishes:

- The development and adoption of biodegradable finishing agents that align with sustainability goals.

- Smart finishes with functionalities such as color-changing properties or responsive textiles.

3. Circular Economy Practices:

- Implementing circular economy practices, including recycling and upcycling of textiles, in dyeing and finishing processes.

4. Advanced Color Management:

- Utilizing advanced color management systems that leverage AI and machine learning for precise color matching and consistency.

5. Innovations in Waterless Dyeing:

- Advancements in waterless dyeing technologies, such as air dyeing or dyeing methods that utilize minimal water.

6. Collaboration with Tech Industries:

- Collaborating with technology industries to explore innovations like conductive finishes for wearable technology or integration of sensors in textiles.

7. Blockchain in Supply Chain:

- The implementation of blockchain technology for transparent and traceable supply chains in dyeing and finishing processes.

- Assurance of ethical and sustainable practices through blockchain-based documentation.

Conclusion

In the grand tapestry of textile creation, Dyeing and Finishing Specialists wield the brushes that infuse fabrics with color, texture, and functionality. Their role is not merely technical; it is an art form that requires a delicate balance of precision and creativity. As the textile industry continues to evolve, driven by the pursuit of sustainability, innovation, and customization, the significance of Dyeing and Finishing Specialists becomes increasingly pronounced. They are the architects of fabric transformation, turning raw materials into garments and textiles that adorn our lives. In the journey from dye pots to finished products, Dyeing and Finishing Specialists stand as guardians of quality, sustainability, and the enduring beauty of textiles.